Maximizing efficiency.

Minimizing footprint.

Ready to save money, optimize space, and reduce carbon emissions?

About us

The Answer to the $20 Billion Empty Container Repositioning Problem

The GenFlat Container is engineered to be a substitute for the standard Marine Container. Built from mild steel and Corten, GenFlat exceeds current strength and rigidity standards.

Once four GenFlat containers are stacked and locked together, they can be lifted as a single unit, ready for multi-modal transport.

Process

Expand

The actuator attaches in 6 locking positions utilizing the traditional industry standard “Twist Locking” mechanism

Unlock

Collapse

The Actuator collapses the GenFlat Container automatically in 80 seconds

Stack

Locking technology stacks 4 empty GenFlats into the exact space of a Marine Container

By the Numbers

*average cost savings from US Midwest to Asia

Cost Savings per FEU Move

Cost Savings per FEU Annual

Cost Savings per FEU Usual Life

GenFlat Value Propositions

Safe and Secure

Multi-Modal Transport

Your Existing Operations Don’t Change

GenFlat Containers lock together when collapsed – 4 collapsed container units take up the space of 1 Standard Marine Container. The GenFlat container makes for secure “multi-modal” transport by train, ocean vessel or over the road truck, maintaining the same handling operations currently in place.

Cost Savings

Reduces repositioning costs by up to 75%.

Space Creating

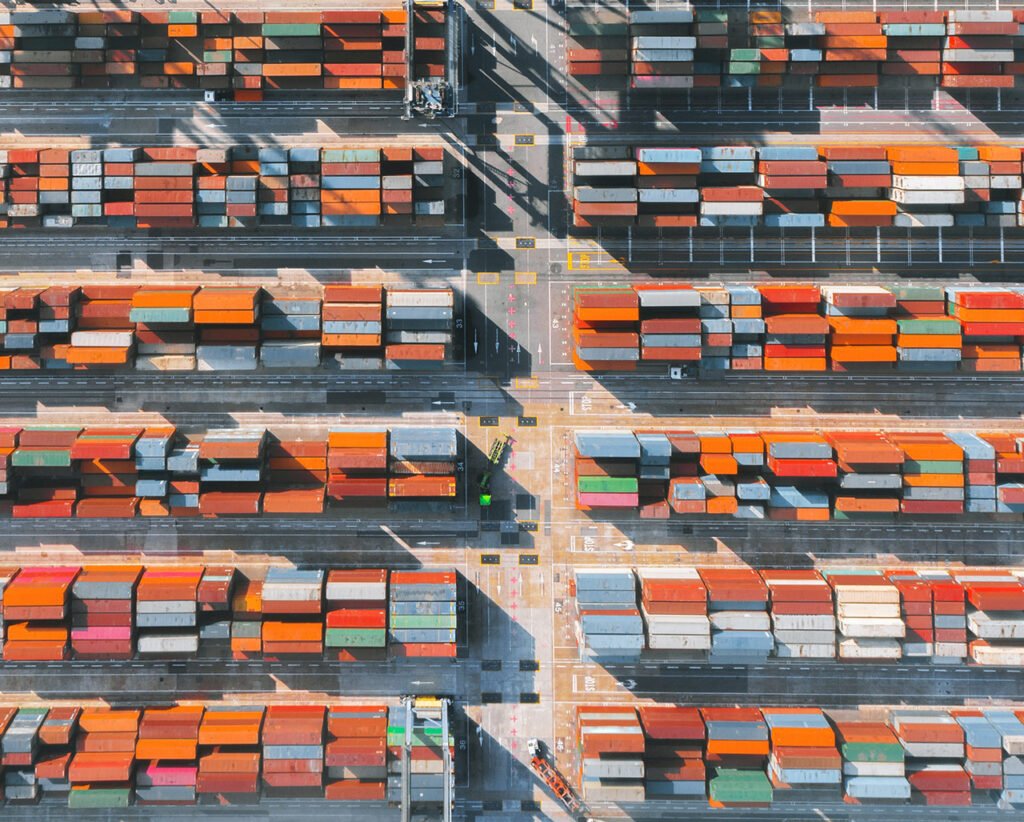

Reduces overall congestion at ports, terminals, depots and related storage facilities and removes the burden of finding solutions to capacity constraints.

Carbon Emission Reduction

Fewer transportation moves = reduced fuel consumption, reduced traffic and reduced emissions

The Actuator is key to collapsing and expanding the GenFlat collapsible container. The Actuator fits all container spreader equipment in the 20’ position. The device lifts the GenFlat container in 6 lifting positions, vs the 4 corner positions standardized for lifting ocean containers – and uses a double-action armature on each end to push in or lower down the end panels when collapsing/expanding.

The device is hydraulically powered with electrical controls, enabling easy connection to the material handling device (Top Handler, Transtainer, Gantry Crane devices). Each of the 6 locking positions utilize the traditional industry standard “Twist Locking” mechanisms. The Actuator is lightweight – under 2 metric tons – and although not designed to lift containers further than the collapsing / erecting design, it does have the mandated safe working load testing and certification required for all lifting equipment worldwide.

Why GenFlat

“FULLY LOADED” – NO DIFFERENCE

- Same internal dimensions

- Same capacity and payload

- Same cargo protection

- ISO tested and certified + water tight

“EMPTY” – 4X THE UTILIZATION OF SPACE

- At ports, terminals, depots and yards – 5 to 20 stacked containers

- Ships – 15,000 to 60,000 stacked containers

- Trains – 2 to 8 stacked containers

- Trucks – 1 to 4 stacked containers

Technical Specifications

Total Length: 40 ft

Tare Weight: 5,300 kgs

Payload: 27,200 kgs

Internal Length: 12,192 mm

Internal Width: 2,438 mm

Internal Height: 2,591 mm